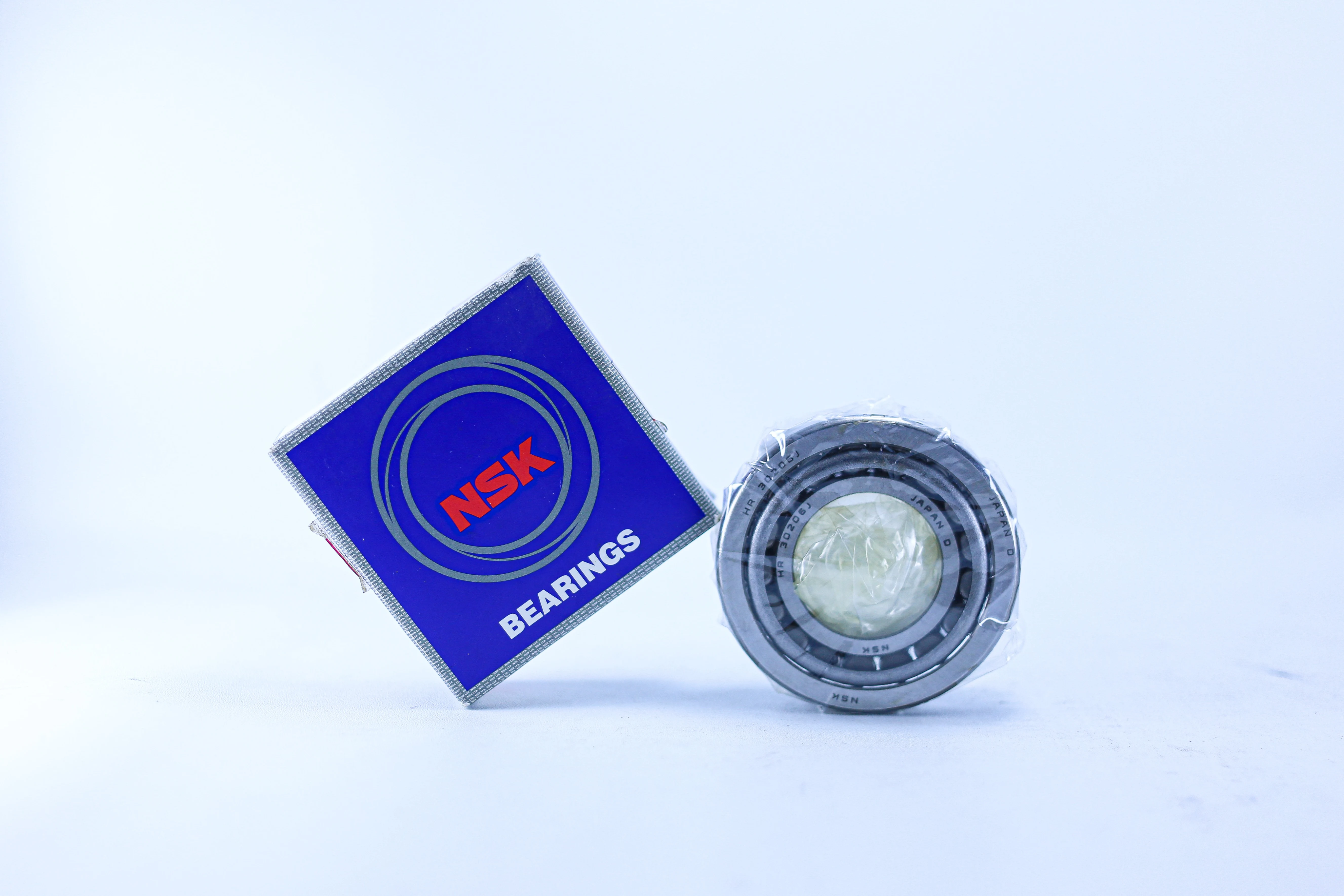

BEARING HR 30206J NSK - 3 Factors to Consider When Shopping for Industrial Bearing Suppliers

BEARING HR 30206J NSK

3 Factors to Consider When Shopping for Industrial Bearing Suppliers

Bearing suppliers are essential for ensuring the smooth running of industrial machinery. Before making a purchase, it is important to understand the factors involved in finding a good supplier. This article will outline three of the most important considerations.

Types of Industrial Bearings

When shopping for industrial bearings, you'll need to consider the type of bearing you need. There are three main types of industrial bearings: journal, radial, and thrust.

Journal bearings are the most common type of industrial bearing. They're used in applications that require a high degree of accuracy, such as automotive and aerospace manufacturing. Radial bearings are used in applications that require high speeds, such as machinery and aircraft engines. Thrust bearings are used in applications that require a lot of torque, such as construction equipment and electric motors.

Wear and Tear

When choosing an industrial bearing supplier, it is important to consider the wear and tear that the bearings will experience. Bearings will require regular maintenance in order to keep them running smoothly.

One of the key factors to consider when selecting a bearing supplier is the type of grease that the bearings will be lubricated with. Different bearing types require different types of grease, so it is important to specify this information when ordering bearings.

Another important factor to consider is the quality of the bearings themselves. Bearings should be selected based on their quality and not their price. Some high-quality bearings may cost a little bit more, but they will last longer and perform better in the long run.

Life Expectancy

When shopping for industrial bearing suppliers, it is important to consider the life expectancy of the bearings. Bearings with a high life expectancy will typically last longer and require less frequent replacement than bearings with a shorter life expectancy.

It is also important to review the quality of the bearings before making a purchase. Bearings that are of high quality will typically have fewer problems and will require less maintenance. Additionally, high-quality bearings typically have a longer lifespan, which means they will require less frequent replacement over time.

Durability

Bearing suppliers must be able to provide a high level of durability for their products.

One of the most important factors to consider when shopping for an industrial bearing supplier is their durability. Bearing suppliers must be able to provide products that are able to withstand a lot of wear and tear. This means that they should have a strong steel frame, heavy duty casings, and high quality seals.

Bearing suppliers should also have a good reputation in the industry. This will help to ensure that you are getting products from a reliable source. Finally, bearing suppliers should offer a warranty on their products. This will give you peace of mind in the event that something goes wrong with your bearings.

Conclusion

When shopping for industrial bearing suppliers, it is important to take into account not only the quality of the bearings themselves, but also the services and support that the supplier offers. It can be difficult to find a reliable and experienced supplier when looking online, so it is worth consulting with several providers before making a decision. Make sure you ask about warranty coverage, availability of technical support, and how quickly they will respond to any inquiries you might have.